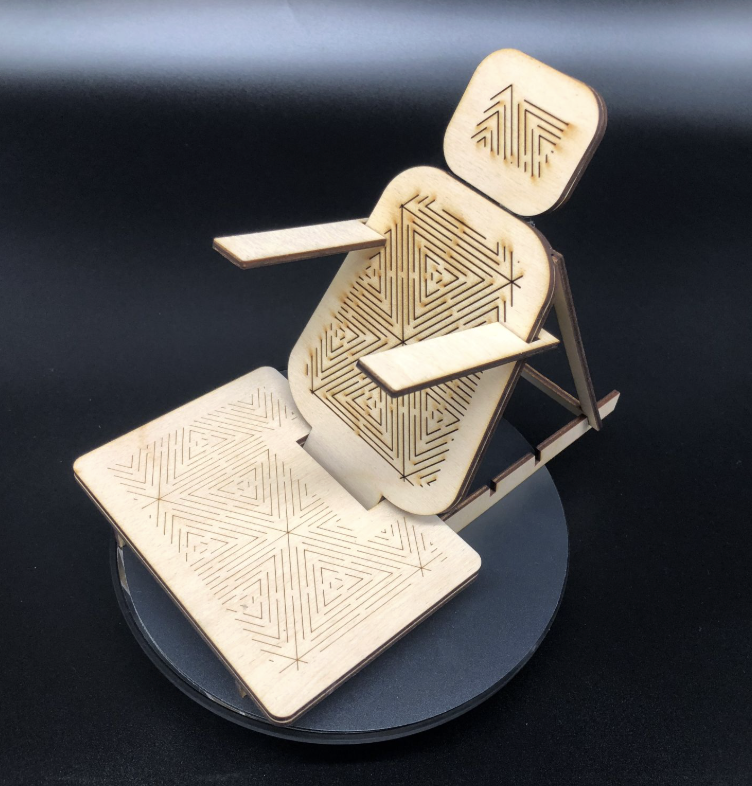

Living Hinge Chair

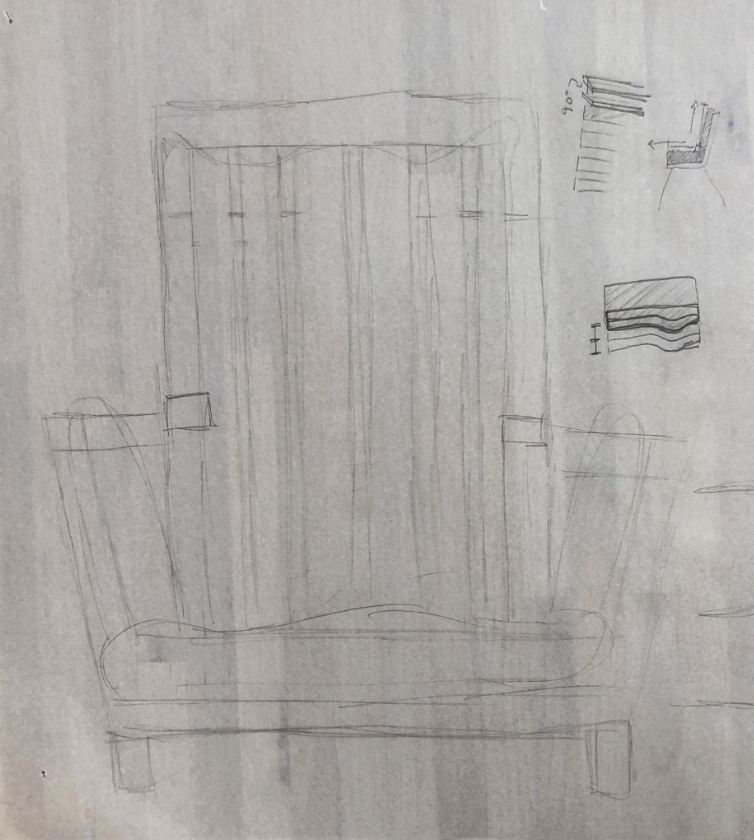

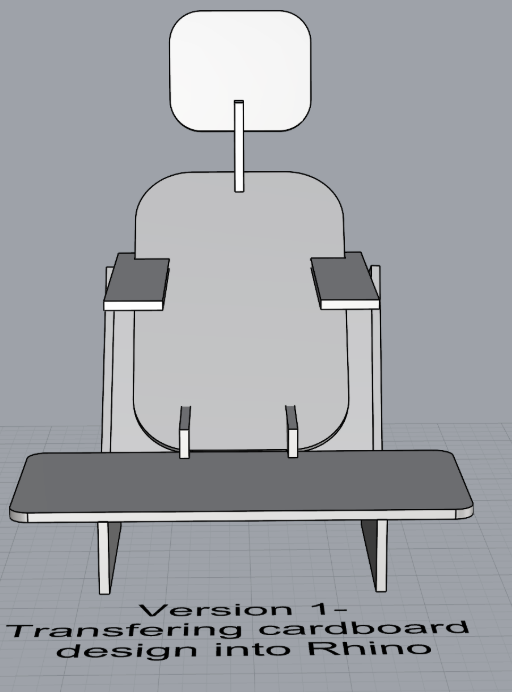

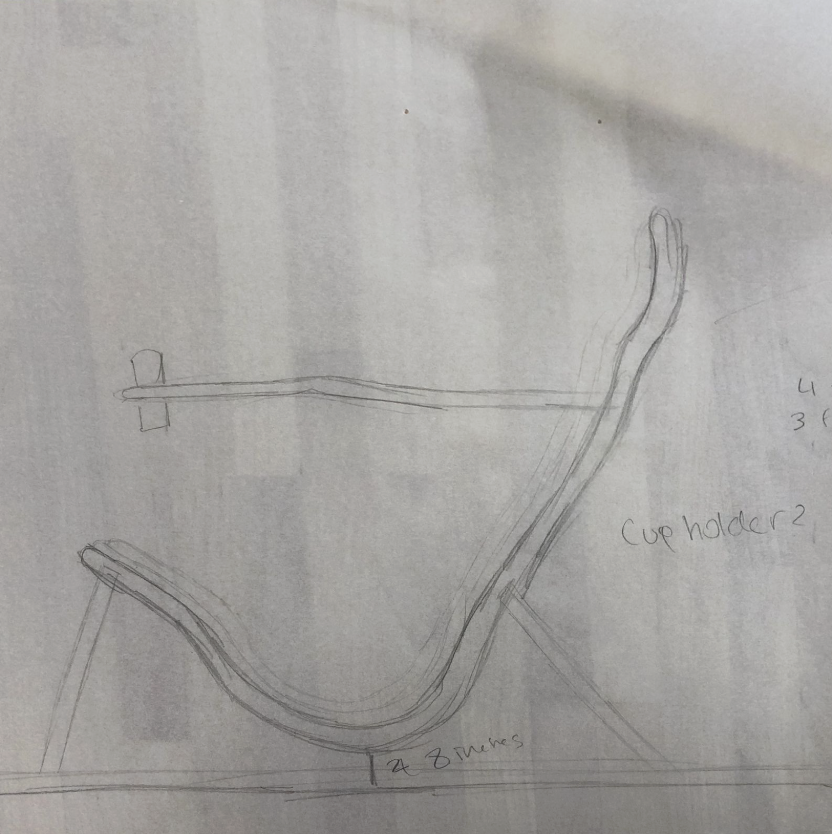

A flat-pack chair inspired by the ergonomics of car seating and the relaxation of a pool lounge, designed with adjustable living-hinge construction and interchangeable patterned panels for easy customization and storage.

Project Scope: Illustration | Typography | Poster Design

Project Duration: Fall 2024 (Semester-long)

Tools Used: Rhino 7 & 8 | Illustrator | Lightroom